Browse by Category

- Expand

- New Products

- Special Offers

- Discounted Items

- Genuine Lotus Parts

- Accessories

- Chassis & Crash Structures

- Corrosion Inhibitors & Lubricant

- Exterior & Bodywork

- Electrically Operated Parts

- Windscreen Wipers & Washers

- Interior Trim

- Brake System & Ancillaries

- Cylinder Head & Ancillaries

- Engine & Components

- Engine Management & Sensors

- Security & Alarm System

- Gearbox & Drivetrain

- Induction Intake System

- Exhaust System

- Ignition System

- Fuel System

- Lighting

- Cooling

- Heating & Air Conditioning

- Track + Performance

- Steering + Suspension

- Wheels and Tyres

- Service and Maintenance

- Tools

- Left Hand Drive Parts

Home › Brake System & Ancillaries › Brake Discs › V6 Exige Rear 343mm Floating Brake Discs

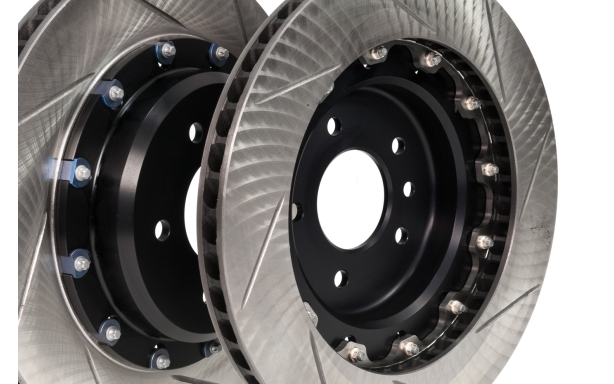

V6 Exige Rear 343mm Floating Brake Discs

Be the first to write a review

V6 Exige 343mm Fully Floating Rear Brake Discs & Bells.

FOR RACE & TRACK USE ONLY

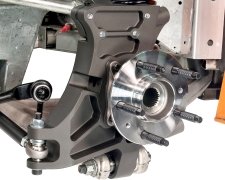

Radial float allows differential expansion of disc and bell thus reducing stresses in the disc and minimising disc cracking and distortion.

The idea of axial float is to compensate for a certain amount of stub axle / upright flex by allowing the disc to take up its ideal position within the range of float thus avoiding "knockback" of the caliper pistons.

The float should not be excessive as disc gyroscopic loads can cause the same effect that the float is trying to alleviate.

The amount of axial float will depend somewhat on the application; we have found that for the later Lotus application with minimal disc movement relative to the caliper the amount of float need only be around 0.10mm - 0.15mm.

Our Floating Disc Bells are the pinnacle, made from Aircraft specification certificated 7075 aluminium, Black Hard anodised for the ultimate in corrosion and wear resistance.

We use the highest quality Titanium for the 12 Disc-Bell bobbins even these are then anodised to reduce the galling that can be caused by constant movement and expansion between the Bell and Disc Bobbin.

The fasteners we use are again the highest specification K locknuts and specially manufactured 12.9 grade Low Head Cap head fasteners which are Delta coated for longest corrosion protection possible.

Cast at the same UK foundry from the highest quality grade of Steel used by AP Racing and other top specification brake disc manufacturers.

Manufactured from NEW casting moulds so the internals line up perfectly and precision machined to ensure consistent brake performance and reliability.

Developed specifically to suit the Lotus V6 range we have improved various areas such as air gaps, curved vanes and wall thicknesses.

Our AP Equivalent Brake Discs utilise state of the art materials and design techniques to offer optimum performance / cooling characteristics.

11mm Larger diameter than the standard 332mm they increase the radial braking forces and dissipate heat better with less likelihood of brake fade.

Grooves help to increase pad bite, reduce fade and deliver exceptional braking performance.

Grooves combat "out-gassing", where gas from the pad bonding agents can form a cushion between pad and disc, greatly reducing braking power.

Grooves continually help de-glaze the brake pads, improving efficiency and reducing disc scoring. They even out-wear across the brake pad faces, increasing the effective contact area and extending brake disc life.

Grooves help dissipate water when driving in poor weather and pump away dust and dirt.

These modifications assist by keeping the overall weight down whilst improving heat dissipation and air flow through the disc rotor.

After heat treatment they are precision ground perfectly flat and dynamically balanced.

Used by many successful international race teams and although these are less expensive than AP or Alcon we offer the same warranty.

Can be supplied with 4 x Special stainless Steel Spacers required for install

Dimensions ; 343mmx 26mm x 212mm PCD

Supplied in pairs (2 x Discs and Bells).

This fits the following models:

- V6 EXIGE / ROADSTER & CUP

- LOTUS 3-ELEVEN